Current

Visit us at the GaLaBau trade fair in Nuremberg from 11 to 14 September 2024 at stand no.: 9-200 hall 9

We look forward to seeing you!

The airter® neo 12140 won the silver medal at Demopark 2023 in Eisenach!

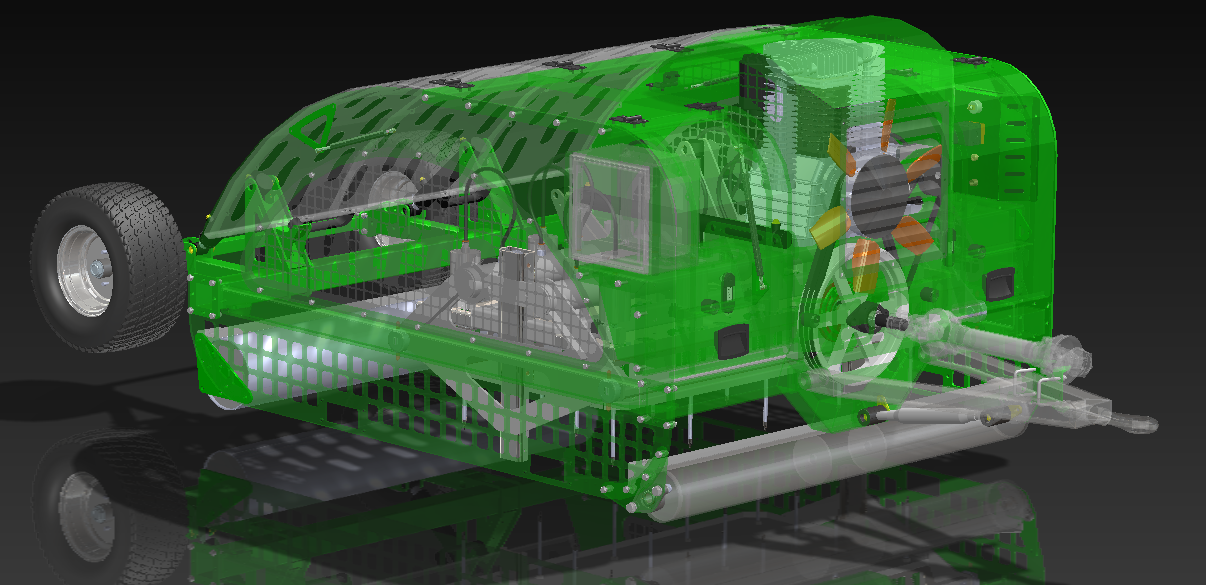

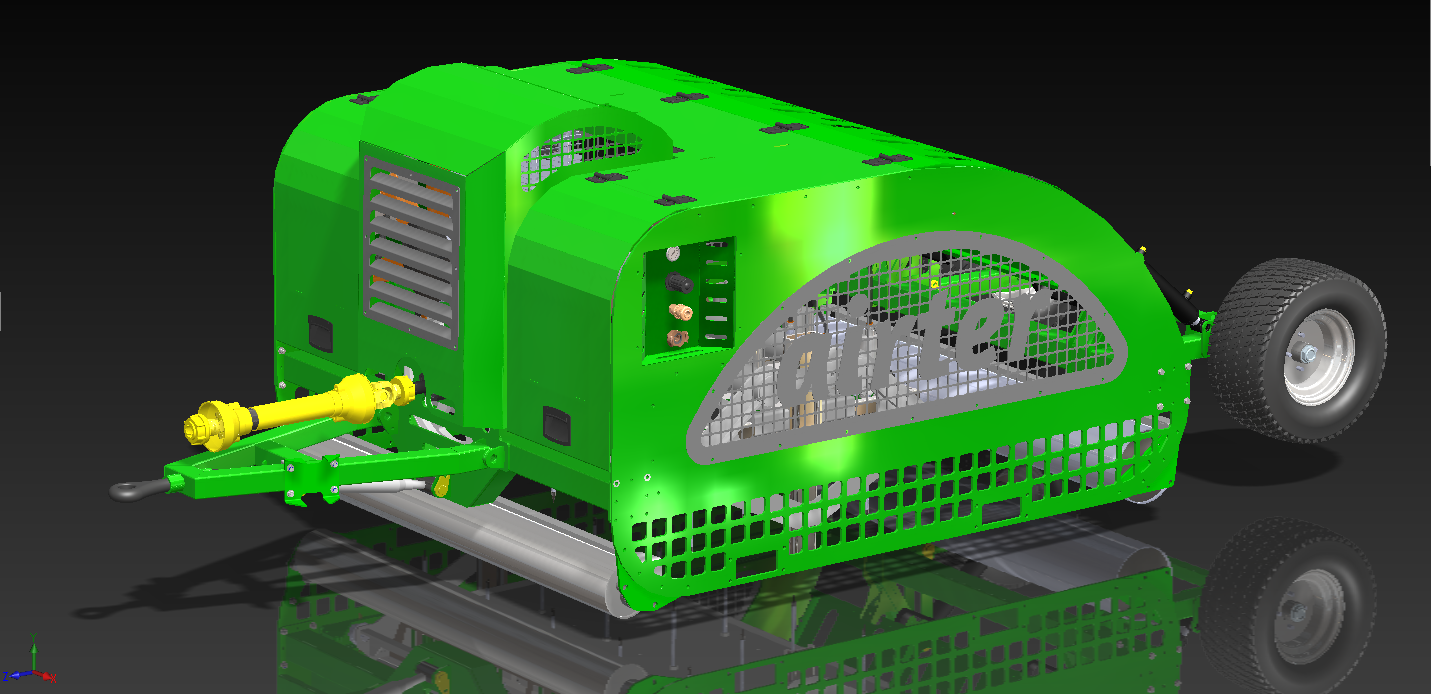

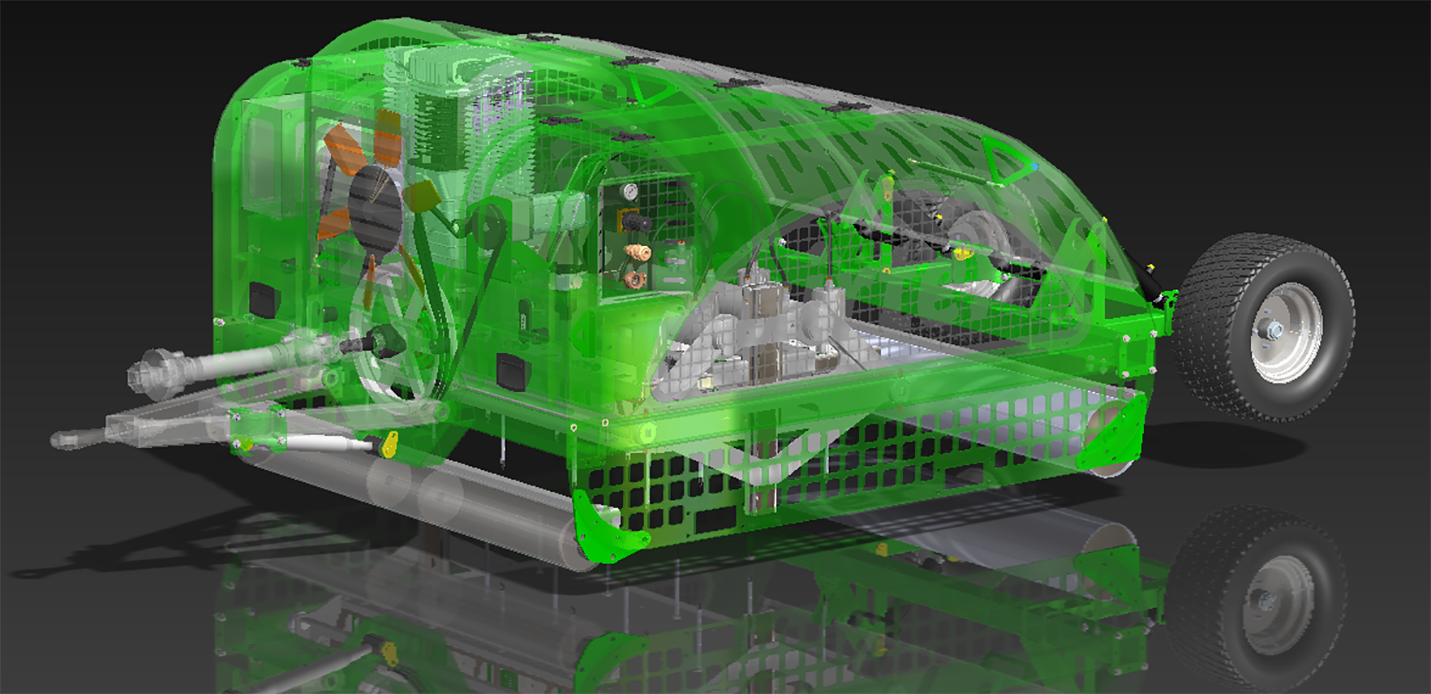

Photos from the airter® trike A 8140

After more than 3 years of development, Novokraft AG is launching two completely redesigned airter machines.

- less susceptible sensors. Simple and solid technology.

- airter neo® 12140 is half the weight (around 550 kg) of its predecessor airter light 14160.

- the airter® trike A 8140 will run autonomously from winter 2023/2024 onwards

- both airters run only on compressed air (without hydraulic oil)

- are twice as fast as its predecessor model (a football field is worked on in about 3-4 hours with the airter® neo)

- no more need to change lances; from -8cm to -20cm can be adjusted quickly and easily without changing directly on the machine

- harmful grubs such as May and June beetles as well as Tipula larvae (Leatherjackets) can be controlled effectively and biologically with 100% compressed air with the airter®.

Enclosed is a selection of new customers who have put an airter light 14160 into operation in 2022 and 2023:

Sommerfeld company from Edewecht, Germany

Company CBZ Sport Construct SA from Sandweiler, Luxembourg

Golf course Golfoase Pfullinger Hof

Proturf GmbH in Winden, Switzerland

Use airter light 14160 in December 2021 at Stade de Genève at FC Servette in Geneva / Switzerland

Photo by Realsport AG, Rossens, Switzerland

TURNIER Tennis- und Sportplatzbau GmbH, Baiersbronn, Germany. Delivered directly from production

Neuer airter light 14160 bei SK Rapid Wien

Neuer airter Kompakt 26190 bei der Fa. Bächler + Güttinger AG in Kiesen

Neuer airter light 14160 bei Fa. Sparfel SA in der Bretagne, FR

Neuer airter light 14160 bei Turnier Sport in Baiersbronn, DE

airter® the sports turf care of the future with active aerification

Unique in the world, the airter® loosens the turf layers homogeneously from 8 cm to a depth of more than 24 cm – with adjustable compressed air and in one continuous operation. 26 specially developed injection lances with different types of nozzles inject up to one million litres of air per working process into the ground of a football pitch. With regard to water infiltration, an improvement can be measured immediately on the treated surfaces. Even football pitches that tend to become waterlogged due to an unfavourable structural quality in terms of material selection and grain size distribution; soil properties as well as an unsuitable choice of substrate could be “defused” by working with the airter® with 2 to 9 bars of air pressure.

Even unwanted and harmful grubs such as May and June beetles as well as Tipula larvae (leatherjackets) can be effectively and biologically controlled with the airter® using compressed air at 100% and guaranteed.

The all-important oxygen, which is dosed into the turf layer by the aeration, ensures stronger roots and thus proven vital plant growth. Anaerobic bacteria are destroyed by the airter® with the supplied oxygen and thus a “black layer” profile layer can never again develop, which has a damaging effect on the soil. There are also no disturbing puncture holes in the soil. This prevents the soil from drying out at high temperatures and there are no holes visible in the greens that could hinder and disturb the course of the golf ball. The golfers do not notice anything on the green from this maintenance measure carried out on the same day. With the airter®, treatment is always possible even during ongoing play without having a negative effect on the playability of the golf greens.

Scientific studies have proven a homogeneous and comprehensive loosening of the soil after tilling with the airter®. Measurements with a penetrometer result in a soil loosening of the turf base layer of at least approx. 30%, which lasts for more than 3 weeks. At the same time, a 23% increase in the amount of cuttings was measured, as well as up to 48% better water drainage in the soil. Proper maintenance of organic golf and football courses in the future can only be achieved with active oxygen in the soil. The first golf operations have already successfully converted to this future form of operation with an airter® and more and more are coming! In addition to the effect of a better, more durable and more beautiful lawn, you also reduce your annual maintenance costs with the airter®. (Reduction of water, pesticides, machines and personnel).

Especially with hybrid lawn systems, the airter® is unbeatable with its effect. Why? Fact: Until now, all hybrid turf systems could only be worked with a full chisel. The hollow chisels, which work better in the soil, are prohibited in all hybrid turf systems because they destroy the artificial fibres. This is a maintenance conflict! A full chisel creates little aeration and its penetration creates undesirable vertical compaction in the turf base layer. The result is poor and hard pitches in the long run. The airter® is the only machine in the world that can demonstrably loosen these hybrid turf systems homogeneously horizontally with compressed air. The quality of a hybrid turf is only sustainably maintained by the airter®.

Good movie of airter operation on a golf course in England:

We would be happy to organize a non-binding demonstration appointment for you at your facility. Convince yourself of the new airter!

Here are the scientifically confirmed facts about the airter:

1. proven soil loosening of the turf base layer and golf greens of at least 30%.

2. soil loosening lasts up to 4 weeks

3. at the same time a 23% increase in grass clippings was measured

4. As well as an up to 48% better water drainage in the soil

5. even the unwanted grubs (May and June beetles) and the Tipula larvae can be effectively and can be effectively and biologically controlled with the airter using compressed air.

6. the oxygen through the aeration provides stronger roots and vital plant growth

7. no more black layer

At the beginning of January 2021, Realsport AG from Rossens also purchased a new airter® light 14160, which is mainly used on the hybrid turf pitches at the Stade de la Tuilière in Lausanne. Realsport AG is the largest company in Switzerland in the field of sports field construction and maintenance. See also under: www.realsport.ch.

At the beginning of December 2020, FC Basel purchased a new airter® light 14160 for its stadium St. Jakob-Park in Basel and for the training ground Nachwuchs-Campus FC Basel. The head greenkeeper of FC Basel, Mr Marc Studach, is absolutely convinced of the positive effect of the airter.

Summary of the important test results

Scientific field test with the airter ® Light 14160 in 2019

on the topic (published in 2020):

Studies on pneumatic floor maintenance on deep cut and hybrid turf.

This on a golf green near Bonn and on Hybrid turf pitch at FC Augsburg (Germany)

Study by Leopold Breloh from the Institute for Agricultural Engineering in Stuttgart, process engineering in plant production

Prof. Dr. Hans W. Griepentrog and Dr. Jörg Morhard

Loosening effect:

Deep cut surfaces: Measuring horizon: 0-35 cm, loosening of 16-28 %, averaged over all data Ø 21 % loosening, maximum achieved loosening of 38

Hybrid turf: Measuring horizon: 0-16 cm, averaged over all data Ø 10 % loosening. Low initial compaction!

Sustainability: loosening could be detected on all test plots up to three weeks after treatment (Ø 11.5 %), occasionally up to four weeks (6 % loosening)

Air void volume: Ø reduction of vol. water content after processing of 13.2

Water infiltration: increase after treatment of 39 % or 46 % (“problem greens”) Sustainability up to four weeks (increase of 17 %)

Ball roll behaviour always improved after machining

On all processed greens an increased amount of cuttings (23 %) could be observed

The experiment was a complete success for the airter and shows scientifically how much added value an airter adds to a sports surface!

Perfect practical demonstrations and great interest in airter® light during the Research Days at STRI in Bingley

At the Research Days on September 25 & 26, 2019 at STRI in Bingley, only the most innovative products and machines were presented. Machines and techniques tested by the STRI Research team to improve the future quality and management of sports turf. The new airter® light 14160 was demonstrated 14 times live on both days. The trade visitors from all over the world were more than enthusiastic about this innovation.

from left to right: Eric Hardman, Novokraft, Rob Baker, STRI, Tom Moore, Fineturf, Roger Holzer, Novokraft

airter® light 14160 in Anfield

This summer, Fineturf as a contractor worked with our airter light 14160 on the entire hybrid pitch in the venerable Anfield Stadium at FC Liverpool. The headgreenkeeper of FC Liverpool was enthusiastic about the positive effect of the airter. Watch the film.

Handover of a new airter light 14160 to Marc Ferguson, Research Manager at STRI

On 13 June 2019, Eric Hardman from Novokraft AG handed over a new airter light 14160 to Marc Ferguson, Research Manager at STRI in Bingley. This airter will be integrated into a large scientific field trial at STRI in Bingley for a period of 12 months. The first results of the field test with the airter will then be available at the STRI Research Days in Bingley on September 25 & 26, 2019

Handover of a new airter light 14160 to our new dealer in Middle England

On 10 May 2019, Eric Hardman of Novokraft AG successfully commissioned a completely new airter light 14160 at Fine Turf’s Simon Hutton. From now on the company Fine Turf from Grantham / England is our new dealer for the whole of Middle England. We are very proud to have found with Fine Turf a very well-known and very innovative dealer. Take a look at the great video where the airter is doing a perfect job on a golf green.

Retrospect

Successful roadshow in the USA in three states South Carolina, North Carolina and Virginia.

Here you can read the detailed report about the roadshow in the USA.

Demopark Eisenach

This year’s Demopark 2019 in Eisenach was again a complete success. The practical demonstration of our new airter® light 14160 to the trade public was very well received and was a great innovation. Our airter® is currently also the only machine that can continuously loosen the various hardened golf and sports turf surfaces with air pressure and fresh oxygen. The scientifically proven loosening of the turf base layer is well over 30%. Likewise, this homogeneous and pneumatic loosening method massively improves all bioactivity in the soil

Golf Industry Show

From February 2 to 7, 2019, the Golf Industry Show took place at the San Diego Convention Center in San Diego, USA. No other event draws more important decision-makers from all areas of the golf industry under one roof. The new airter light 14160 was on display for the first time at the Stec Equipment stand in San Diego. The fair was a complete success!

The booth of Novokraft at the biggest golf fair BTME in Harrogate / England in January 2019 and the simultaneously held STME golf fair in Phoenix, Arizona, USA at the booth of Stec Equipments was a complete success. The presentation of our new machine airter® light 14160 as a world novelty in the ventilation and loosening of sports, golf and hybrid turf inspired the visitors in England and the USA. A lot of trade visitors were interested in the airter. The completely redesigned, pneumatic soil aeration device for professionals loosens the soil homogeneously and to a depth of more than -24 cm. This is done using compressed air and in a continuous operation (i.e. a football field is completely worked in 8 hours). 14 specially developed injection lances push up to 1 million litres of air per playing field into the ground in a continuous and efficient working process. Our airter® is currently also the only machine that can demonstrably loosen the various hardened hybrid turf systems. The scientifically proven loosening of the lawn base layer is well over 30%. Practical tests on a new hybrid turf field have shown that with the loosening by our airter® the players felt the field to be much softer afterwards. This homogeneous and pneumatic loosening method also massively improves the entire bioactivity in the soil.

The demonstration of the airter® light 14160 in Basel, Nuremberg and Leverkusen was a great success.

- Faster and cheaper

- Completely reworked machine

- Drawn machine with only 950kg weight

- New airsoftroll® roller system for lowest ground pressure (rear tyre roller)

- For all tractors from 30 to 45 HP

- working width 160cm with 1100qm area output per hour

- For all natural grass and hybrid turf systems

- Quick-release closure for the 14 injection lances

- Simple operation for everyone

- New: Especially now also suitable for golf courses

Brand new on the market in autumn 2018

The loosening for the best lawn

airter® light 14160- technique

The pneumatic soil aeration device for professionals loosens the soil homogeneously and to a depth of more than -22cm – this with compressed air and in a continuous operation (a football field is completely worked in 8 hours). 14 specially developed injection lances push up to one million litres of air per playing field into the ground in a continuous and efficient working process. The airter® is currently the only machine in the world capable of loosening the various hardened hybrid turf systems. Here, enormous growth potential is to be expected. Practical trials on a new Grass Master hybrid turf field in Germany have shown that the players felt much softer after loosening with airter®. This homogeneous, pneumatic loosening method also massively improves the entire bioactivity in the soil.

A world novelty – airter®

The revolution in professional lawn care!

Fresh oxygen for sports turf, golf turf and hybrid turf

Other unrivalled advantages:

- Guaranteed continuous and fast infiltration of meteowater

- Excellent for the hot summer months

- No more drying out of the field due to too large puncture holes

- The lawn base layer is perfected for better water and nutrient absorption

- The optimal care of the lawn base layer can directly save maintenance costs.

- The sports turf immediately becomes softer and optimally playable again

- All bioactivity in the soil is massively improved

- Thus best and quick regeneration of the lawn

Advantages and arguments over competitors

- Continuous operation (simple machine operation)

- Scientifically validated system (Uni Hohenheim DE)

- efficient working process (a playing field can be processed within one day)

- Low personnel costs

- Employee can drive in tractor

- No own combustion engine (thus less service effort)

- effective and regular ventilation of the root horizon

- targeted injection of compressed air

- Homogeneous and precise loosening of the lawn base layer

- Surface and deep loosening in one pass

- At least 30% measurable homogeneous loosening of the lawn-bearing layer/soil laye

- 14 puncture lances from 8 to 18 cm variably usable

- Compressed air steplessly controllable from 1 bar to max. 10 bar

- Due to the vacuum plate pressed to the floor and the small distance between the injection lances, the air in the floor has to compete with each other (homogeneous loosening).

- Penetration depths of 8 to 18 cm are ideal for the lawn base layer

- airter® is available in different models (large or small, towed or mounted)

- Compressed air connection on airter® possible for other compressed air work (pneumatic hammer or drain pneumatic hammer lance)

- No drying out of the playing field thanks to minimum puncture diameter

- No uneven green thanks to minimal puncture diameter

- airter® is probably the only machine/method worldwide for the new hybrid turf that loosens and ventilates the soil sustainably in 8 to 10 hours (football pitch).

- airter® pumps between 750,000 and 1,000,000 litres of air/oxygen into one football pitch per round

- Loosening of hardened hybrid lawn base layers (prevention of the formation of rotting gases)

- airter® one additional unit for ventilation of the lawn base layer around sprinklers and sleeves

- Various granted patents and further patent applications

- The costs for the purchase of the airter® are the same as for the competing product – but the airter is 3 times faster and qualitatively 6 times better!

- Discontinuous operation (stop and go)

- Inefficient work process (a playing field can be processed within three days)

- High personnel costs

- Employees have to run after them

- Own combustion engine (thus more service effort)

- Irregular ventilation of the root horizon

- Arbitrary injection of compressed air

- Random and irregular loosening of the lawn base layer

- No measurable, homogeneous loosening of the lawn base layer, but randomly loosened spots

- Only 3 puncture lances from 17 to 25cm can be used

- Compressed air steplessly controllable from 1 bar to max. 7 bar

- Small pressure discs and large distance between the lances, therefore no competitive behaviour in air injection (no homogeneous ventilation possible)

- There is only one model from the competitor (no selection possible, also no stronger row in the assortment)

- No large connection for compressed air work on the device, thus no possibility for connection of Drain compressed air hammer lance

- Also no drying out of the playing field thanks to minimum puncture diameter

- Also no restless green thanks to minimal puncture diameter

- The competitor product is not suitable for aerating and loosening large hybrid lawns (too slow, not homogeneous, not sustainable and therefore not economical). A football pitch needs at least 3 days.

- The power of the compressor is not enough to bring this analogue amount of air into the ground.

Awards

Eric Hardman, Head of Sales and Development, accepts the award from Mr August Forster, President of the Federal Association for Garden, Landscape and Sports Field Construction (Bundesverband Garten-, Landschafts- und Sportplatzbau e. V.). (left in picture) and Ulrich Schäfer, Galabau Trade Fair Advisory Board and President of the Bavarian Garden, Landscape and Sports Field Construction Association. (right in the picture).